Service Appointment & Enquiry

Customer Service Tel: 4000-0750-68

Service Appointment & Enquiry

Customer Service Tel: 4000-0750-68

Recently, the Electrical and Automation Branch of the Guangdong Engineering Survey and Design Industry Association visited Haihong Electric for in-depth discussions on technological innovation in electrical equipment, industry development trends, and the diverse application scenarios of 3D wound core technology. As a global leader in 3D wound core transformer technology, Haihong Electric has consistently embraced open collaboration, actively integrating industry resources to drive energy efficiency upgrades and high-quality development in the electrical sector through continuous innovation and forward-thinking application solutions.

Driving Industry Innovation with 3D Wound Core Technology

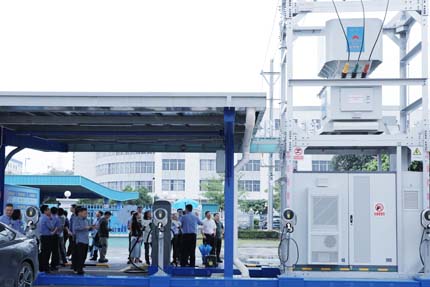

During the exchange, the delegation toured Haihong Electric’s world-leading 3D wound core manufacturing base, including its open-type electrical production workshop, prefabricated substation production facility, CNAS-accredited testing center, and 3D wound core technology exhibition hall. The company showcased its independently developed 3D wound core transformer technology, which replaces traditional laminated core planar structures with a balanced three-phase design, significantly reducing operational losses and noise while improving energy efficiency. This technology has been widely adopted in emerging fields such as renewable energy, rail transit, data centers, and charging stations.

Industry experts praised Haihong’s achievements, noting that the technology “not only aligns with the industry’s needs under the ‘dual-carbon’ goals but also offers a fresh approach to power distribution system upgrades with its differentiated advantages.”

Haihong’s technical lead emphasized that innovation must stem from real-world demands. Through extensive research and on-site evaluations, the team has refined product designs to address user pain points. In the charging station sector, Haihong leveraged its compact, modular prefabricate substation design to create an integrated one-stop charging station, featuring a small footprint and high reliability, easing construction challenges in land-scarce areas. For rural EV adoption, the company’s modular smart charging stations—energy-efficient, safe, and cost-effective—have resolved issues like high installation costs, excessive civil engineering requirements, and equipment wear, supporting the nationwide push for new energy vehicles in rural regions.

Open Collaboration for Mutual Success, Partnering with Associations to Advance Industry Progress

The discussions also covered industry development and academia-industry collaboration. Haihong stressed that its growth relies on deep cooperation with industry associations, design institutes, and peers. By participating in industry forums, technical standard formulation, and joint research projects, the company has expanded the reach of its 3D wound core technology while incorporating feedback to fuel R&D, creating a virtuous cycle of “technology-market-feedback.”

This event highlighted Haihong’s philosophy of “grounding growth in technology and fostering open win-win partnerships.” Under the “dual-carbon” goals and the digital transformation wave, Haihong Electric is leveraging its 3D wound core technology as a cornerstone, working with industry partners to unlock a brighter future for the electrical sector.

*The copyright of the above picture belongs to HAIHONG Electric Co., Ltd.Please contact for authorization if you need to reuse it.