Service Appointment & Enquiry

Customer Service Tel: 4000-0750-68

Service Appointment & Enquiry

Customer Service Tel: 4000-0750-68

Reliability and energy efficiency of electrical equipment are paramount during offshore platform operations. Recently, the life-extension retrofit project of the Panyu offshore platform in the South China Sea adopted HAIHONG Electric’s 3D Wound Core Oil-Immersed Transformers to upgrade its power distribution system. With advantages including high safety/reliability, low losses, and strong corrosion resistance, this product delivers stable power assurance for the platform.

The "Robust Heart" of the Power System

HAIHONG Electric’s innovative 3D Wound Core transformer design resolves issues prevalent in traditional laminated-core transformers—such as vibration susceptibility and high temperature rise—equipping the offshore platform with a "robust heart" for power supply.

· Balanced Three-Phase Performance: Identical and minimized magnetic path lengths significantly enhance operational efficiency and reliability, improving power stability on the platform.

· Superior Short-Circuit Withstand: The core, wound from silicon steel/amorphous alloy strips, is seamless, structurally compact, and boasts high overall strength with uniform stress distribution. This effectively withstands harsh offshore operating conditions, ensuring continuous stable power supply and reducing unplanned outages caused by transformer failures.

· Uniform Temperature Field: Optimized oil duct design in transformer windings enables high heat dissipation efficiency and low hotspot temperature rise. With lower operating temperatures, the product meets operational requirements in high-temperature offshore environments (ambient temperatures up to 50°C).

Specialized Anti-Salt Spray Design

Tailored for high-salt, high-humidity marine environments:

· Terminal Protection: HV/LV terminals feature anti-salt-spray and anti-dust protective covers, effectively shielding transformer terminals and copper busbars from corrosion.

· Material & Coating Protection: Critical components use premium stainless steel combined with C5-M grade anti-corrosion coating to resist high-salt environments.

· Sealed Construction: High-integrity tank sealing complies with offshore explosion-proof requirements and prevents oil leakage.

Notable Energy Savings

3D Wound Core Transformers deliver significant energy savings compared to laminated-core transformers (at equivalent cost):

· No-load loss reduced by 30%

· Load loss reduced by 5%

· No-load current reduced by 70%

Beyond enhancing power stability, their low-loss characteristics minimize energy waste, supporting cost reduction and efficiency gains for offshore oilfields.

Adaptability to Specialized Applications

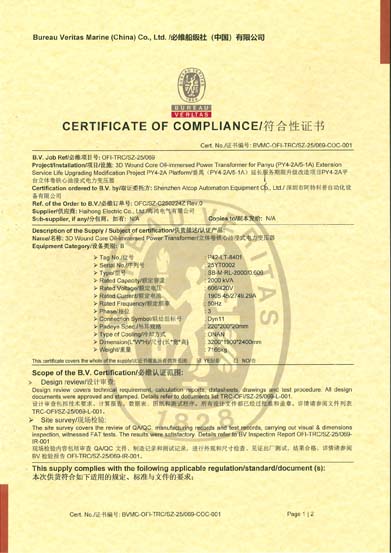

The deployed products have obtained Bureau Veritas Marine (China) CERTIFICATE OF COMPLIANCE and meet all technical requirements for offshore platform operations. This project demonstrates the flexibility and adaptability of 3D Wound Core Transformers, which can be custom-designed for specialized operational demands. They provide safe, highly reliable, and energy-efficient power distribution technology to tackle complex electrical and harsh operating environments, supporting system upgrades in ports, marine vessels, offshore platforms, and other specialized fields.

Offshore platform equipment upgrades and green transition are concrete actions toward achieving "dual carbon" goals. Leveraging innovative technology and precision engineering, HAIHONG Electric’s 3D Wound Core Oil-Immersed Transformers deliver safe, reliable, low-carbon green equipment support for offshore platforms. Moving forward, HAIHONG Electric will continue refining its technology to provide highly reliable power solutions for more offshore energy projects, empowering green transformation in specialized sectors through innovation. From land to sea, HAIHONG Electric’s 3D Wound Core power distribution technology is building a robust and reliable electrical foundation for China’s energy revolution and green development.

The above data is for reference only.

All copyright of the above pictures and text belongs to Haihong Electric. Please contact us for authorization if you need to reprint.