Service Appointment & Enquiry

Customer Service Tel: 4000-0750-68

Service Appointment & Enquiry

Customer Service Tel: 4000-0750-68

To promote the high-quality development of heavy-duty truck electrification, we must address the multiple severe challenges faced by charging and swapping stations: megawatt-level power impacts, continuous high-temperature environments, prolonged ultra-high load operations, dust erosion, and more. Practical engineering experience shows that Haihong Electric's Miniaturized Double-Layer Double-Transformer Substation provides a perfect solution.

One Unit Replaces Two, Reducing Station Construction Costs

Heavy-duty truck fast-charging stations require high operational power, and power supply bureaus often impose capacity limits on individual transformers, necessitating multiple substations to meet distribution needs. To reduce construction costs, a fast-charging station in Yangjiang adopted Haihong Electric’s patented Double-Layer Double-Transformer Substation. This innovation not only significantly lowers initial project costs—including equipment purchase and civil construction expenses—but also achieves the efficiency of "one unit replacing two." It has become a "sharp tool" for cost control and an "accelerator" for improving construction efficiency at heavy-duty truck charging and swapping stations.

Exceptional Performance Meets Stringent Challenges

Heavy-duty truck charging and swapping stations are often located in remote areas with high dust levels and extreme load fluctuations: high-load continuous operation at night (00:00–08:00) and near-idle conditions during other times. Traditional substations lack energy efficiency and stability, leading to accelerated insulation aging, coil insulation cracking, excessive losses, and even failures.

Load Variation Diagram of a Heavy-Duty Truck Charging Station

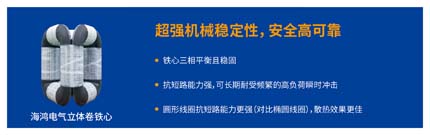

The Miniaturized Double-Layer Double-Transformer Substation excels in energy efficiency, mechanical strength, and insulation performance. It effortlessly handles prolonged ultra-high load operations, resists moisture and dust erosion, and ensures stable operation in extreme environments.

Ultra-Low Temperature Rise Solves Overheating Challenges

Equipped with Haihong’s self-developed Zero-Carbon Vortex Boost Scalable Cooling System, the Miniaturized Double-Layer Double-Transformer Substation further enhances heat dissipation, significantly improving cooling performance.

Data from a Yangjiang fast-charging station shows:

After 2 hours of full-load operation, Haihong’s substation recorded a temperature of only 82.4°C.

In contrast, a competitor’s 1000 kVA substation reached 106.9°C after 2 hours at 84% load.

Additionally, some charging stations using traditional epoxy resin dry-type transformers require air conditioning for cooling, which increases load and raises overall station power losses.

Strong Stability Ensures Continuous Operational Revenue

Due to insufficient transformer stability, some heavy-duty truck charging and swapping stations have had to downgrade fast-charging piles to slow-charging piles, resulting in reduced revenue.

Haihong Electric’s substation solution for heavy-duty truck charging and swapping addresses these operational challenges one by one, ensuring stable and efficient charging performance while avoiding financial losses caused by power distribution issues.

At a supercharging station in Meizhou, 18 × 320 kW DC dual-gun fast-charging piles are supported by 4 Haihong substations, enabling simultaneous charging for 36 new energy heavy-duty trucks.

The reliability and energy efficiency of Haihong Electric’s substation solution have been proven in multiple projects, providing a safe and highly reliable power distribution foundation for heavy-duty truck electrification. This supports China’s green transformation in transportation and contributes to building a strong transportation network.

The above content is the property of HAIHONG Electric Co., Ltd. For reprint authorization, please contact the company directly.