Service Appointment & Enquiry

Customer Service Tel: 4000-0750-68

Service Appointment & Enquiry

Customer Service Tel: 4000-0750-68

Haihong Electric's 110kV 3D Wound core Power Transformer Technology Selected for National Recommendation to International "Top Ten" List

Haihong Electric's 110kV 3D Wound core power transformer technology has been included in the China's Proposed List of Energy-Saving Technologies and Practices Recommended for International "Top Ten" Selection under the category of energy-saving technologies in the industrial and information technology sector. This honor not only signifies the nation's high recognition of Haihong Electric's technological innovation capabilities but also serves as an important pathway for Haihong Electric to step onto the global stage and showcase China's leading level in energy-saving transformers.

3D Wound core Technology: Years of Accumulation, Breakthrough to 110kV Voltage Level

Since 2004, Haihong Electric has been fully engaged in the research and development of 3D Wound core technology. In 2007, the company transitioned entirely to the production and sales of 3D Wound core transformers, successfully pioneering a niche market for energy-saving transformers with this technology, which has gained recognition from both the market and the state. During a visit to Haihong Electric in 2010, Su Bo, former Vice Minister of the Ministry of Industry and Information Technology and Director of the National Intelligent Manufacturing Expert Committee, expressed his hope that Haihong Electric would apply the 3D Wound core technology to power transformers of 110kV and above, thereby fully leveraging the energy-saving and environmental advantages of the technology to create the world's most advanced transformers. After a year of preparation, Haihong Electric officially initiated the research and development of 110kV (132kV) 3D Wound core power transformers in 2011. Through four years of exploration and nearly 90 million yuan in R&D investment, Haihong Electric successfully developed the world's first 110kV 3D Wound core power transformer in 2015, which passed all tests conducted by national-level inspection agencies in 2016. In 2018, the technological achievement was appraised, with its comprehensive technology reaching international advanced levels, particularly in noise reduction and loss reduction, where it leads globally. By 2019, the transformers were being deployed in bulk. In 2022, the SZ22-RL-63000/110-NX1 3D Wound core power transformer, the first and largest-capacity 110kV 3D Wound core power transformer within the Southern Power Grid, was successfully put into operation at the Dunhou Substation in Foshan's Chancheng District. The 110kV 3D Wound core power transformer technology has long been included in the Southern Power Grid's new technology catalog and has been successively deployed in substations, waste-to-energy plants, large manufacturing enterprises, and industrial and mining facilities across the country.

3D Wound core Technology Drives Industry Transformation and Supports Sustainable Energy-Saving Development

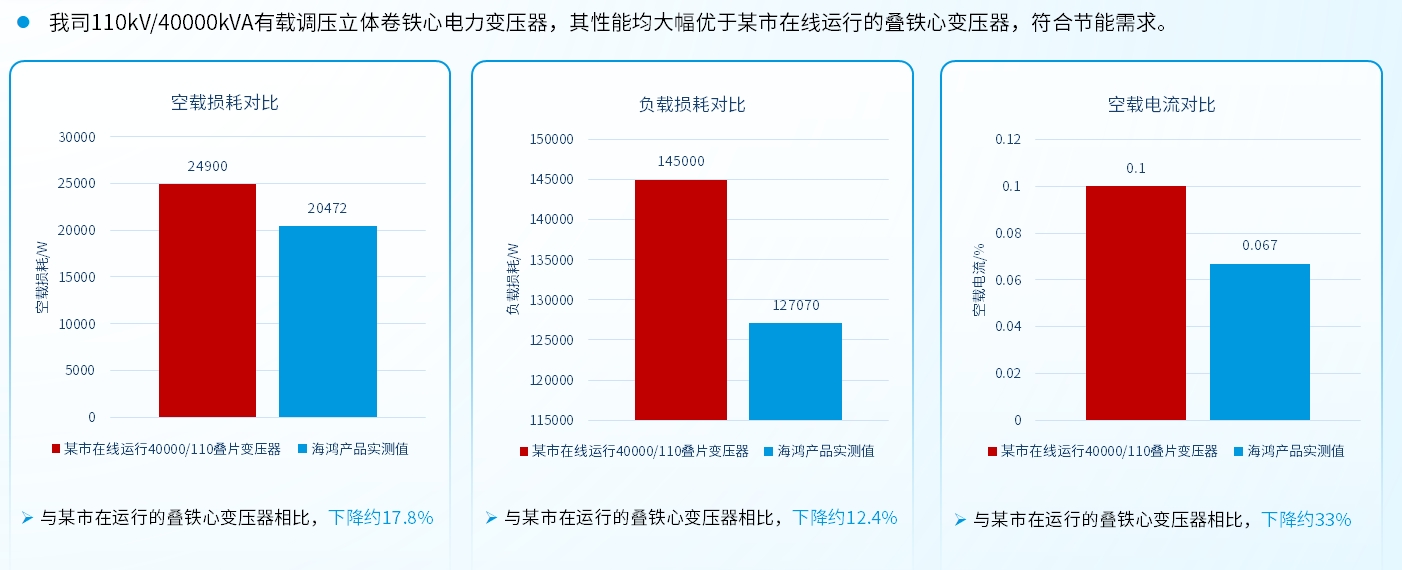

Haihong Electric's 110kV 3D Wound core power transformer technology adopts an advanced 3D Wound core structure, which significantly improves several key performance metrics compared to traditional laminated core transformers: enhanced short-circuit resistance, lower temperature rise, reduced partial discharge, a 50% overall decrease in surrounding electric and magnetic field intensity, and a 10-25 decibel reduction in operational noise. The energy-saving effects of this technology are remarkable. For example, the 110kV/40000kVA on-load tap-changing 3D Wound core power transformer significantly outperforms laminated core transformers currently in operation in a certain city.

The 110kV 3D Wound core transformer also boasts strong compatibility. The transformer body is equilateral triangular, and the tank is nearly square, ensuring even heat distribution and dissipation on all four sides. Radiators can be arranged around the tank as needed to control the transformer's dimensions, meeting installation requirements for different sites while ensuring ease of maintenance.

The advantages of Haihong Electric's 110kV 3D Wound core transformers have been validated by the market, but the development process continues. To achieve a qualitative leap in the energy-saving performance of high-voltage power transformers, Haihong Electric is currently developing a 110kV amorphous alloy 3D Wound core power transformer, fully leveraging the advantages of amorphous alloy roll-core technology. Preliminary results have already been achieved, and future efforts will drive transformative advancements in 110kV 3D Wound core transformers.

This inclusion in the China's Proposed List of Energy-Saving Technologies and Practices Recommended for International "Top Ten" Selection is a powerful affirmation of Haihong Electric's relentless efforts in energy-saving technology R&D over the years. Moving forward, Haihong Electric will continue to uphold its spirit of innovation, constantly optimizing and upgrading its 110kV 3D Wound core power transformer technology to further enhance its performance. At the same time, Haihong Electric will actively participate in international exchanges and collaborations, promoting the global adoption and application of energy-saving technologies, and contributing to the green transformation of the global energy industry.