Service Appointment & Enquiry

Customer Service Tel: 4000-0750-68

Service Appointment & Enquiry

Customer Service Tel: 4000-0750-68

Driven by the "Dual Carbon" goals, Haihong Electric has consistently fulfilled its "green development" mission through technological innovation, actively responding to the national call for energy conservation and carbon reduction. The company has deeply participated in government-led energy efficiency diagnostic initiatives for manufacturing transformer equipment. By leveraging its energy-saving 3D Wound Core technology, Haihong Electric addresses critical power consumption challenges, injecting robust momentum into industrial green transformation.

A recent energy-saving retrofit project at an electronics technology enterprise in Huizhou once again demonstrated the superior performance and high cost-effectiveness of Haihong Electric's green transformers. The facility originally operated three resin-cast laminated-core dry-type transformers for over 14 years. These units consistently ran at high load rates, generating significant noise, high losses, and exhibited cracked resin insulation layers. With production capacity expansion plans underway, an urgent transformer upgrade was essential.

High operating temperature rise, requiring additional ventilation systems for cooling.

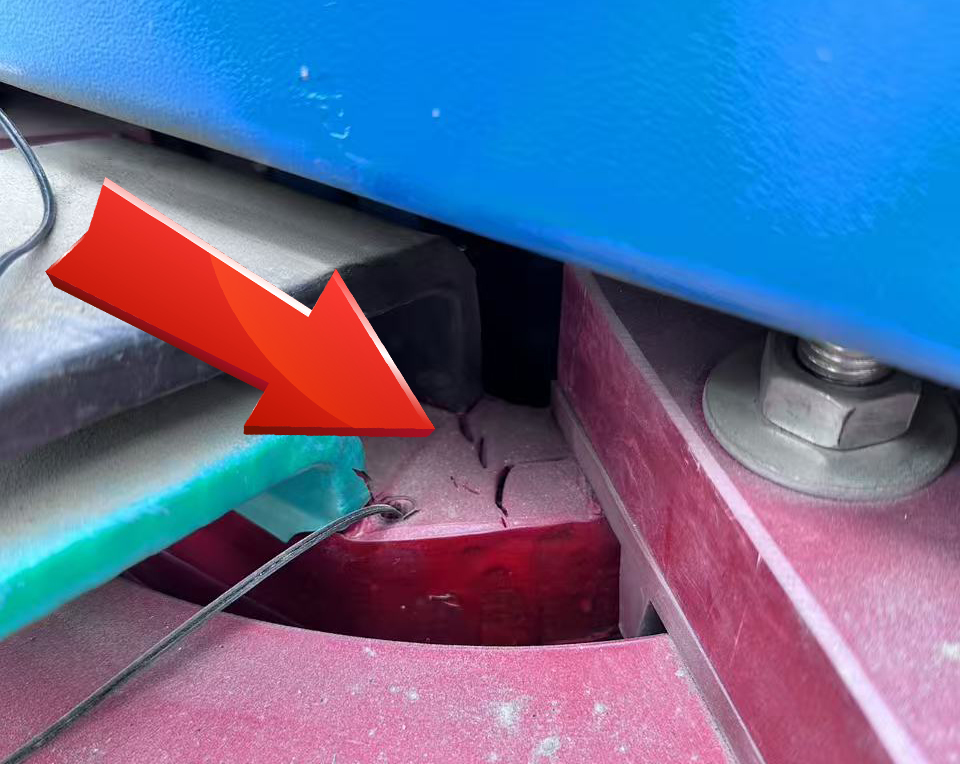

Cracked resin insulation layers in the original resin-cast laminated-core dry-type transformers.

Cracked resin insulation layers in the original resin-cast laminated-core dry-type transformers.

Haihong Electric delivered a tailored energy-saving retrofit solution, replacing the old transformers with same-capacity Class 14 Fully Insulated Low Temperature Rise 3D Wound Core Dry-Type Transformers. The solution offers distinct advantages:

· Precise Capacity Matching: The retrofit plan was designed based on actual load requirements, scientifically planning the power distribution scheme to avoid unnecessary capacity expansion costs and facilitating a low-cost transformer upgrade.

· Exceptional Energy Savings with 3D Wound Core Technology: Post-retrofit, the project is expected to save over 80,000 kWh annually, reducing electricity costs by more than CNY 60,000. (Data for reference)

· Enhanced Safety & Reliability with Ultra-Low Temperature Rise Technology: Significantly improves operational safety and reliability. The transformers feature low operating temperature rise, reduced losses, and strong overload capacity, readily meeting future power demands from production increases.

· Significant Noise Reduction: The Fully Insulated Low Temperature Rise 3D Wound Core Dry-Type Transformers operate quietly.

· Efficient, Rapid Installation: The installation team, through meticulous pre-planning and preparation, demonstrated remarkable efficiency. During the National Day holiday, they completed equipment removal, installation, and commissioning within a single day, earning high praise from the client for their professional service.

On-site Installation

This project stands as a successful case study in equipment upgrade, reflecting Haihong Electric's commitment to serving national strategies through green technology. Centered on its 3D Wound Core technology, Haihong drives transformative improvements in transformer efficiency, offering replicable and scalable solutions for large-scale transformer retrofits.

Fully Insulated Low Temperature Rise 3D Wound Core Dry-Type Transformer

Haihong Electric remains dedicated to innovation in energy-saving technologies, collaborating with partners across sectors to contribute to a greener, low-carbon, safe, and highly reliable energy system. Energy-saving transformation begins with each green product deployed on the production front. National green development is achieved through every application of energy-efficient technology. Haihong Electric is steadfast in its commitment as an active practitioner of the "Dual Carbon" strategy, striving with determined action.

The above content is the property of HAIHONG Electric Co., Ltd. For reprint authorization, please contact the company directly.